Ultra-Fast Automated Press-Side Color Control

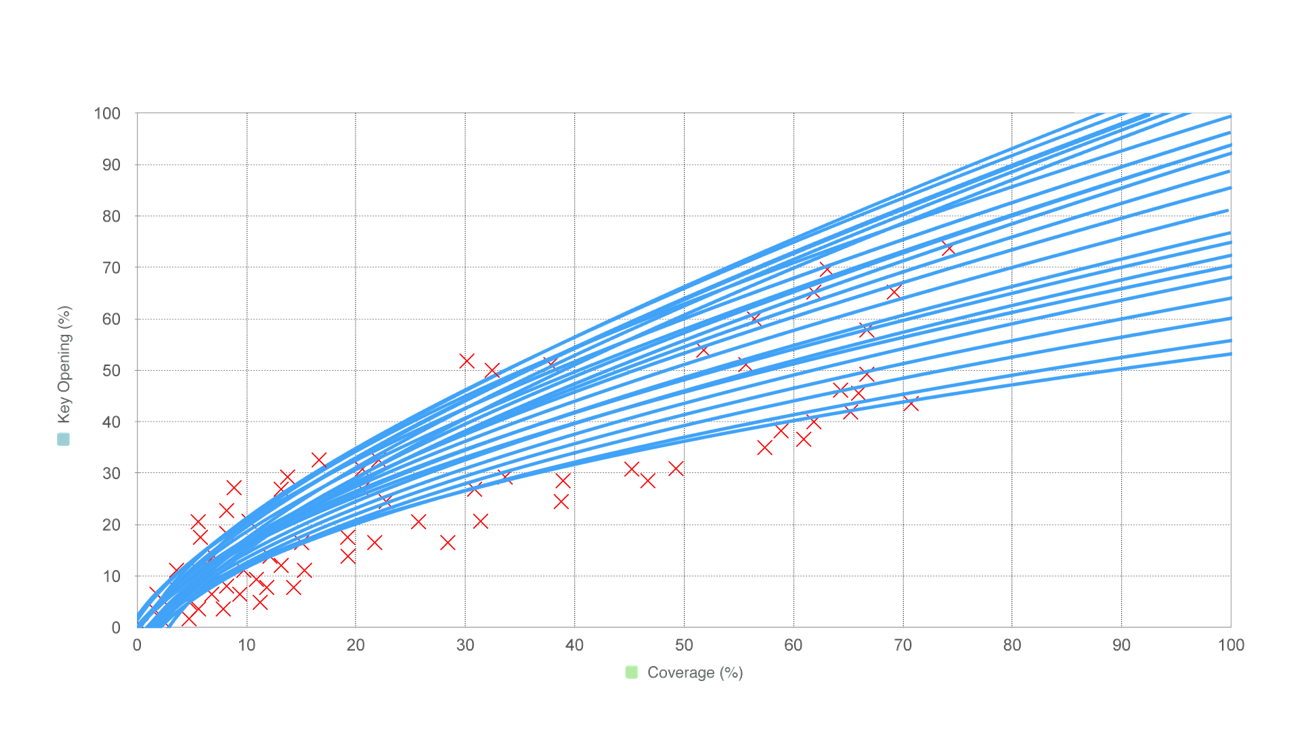

To remain competitive, printers and packaging converters must focus on reducing make-ready time and waste, and minimizing errors and rework. Managing color by eye and/or depending on ink density measurements will not deliver against these requirements. Introducing IntelliTrax2 into the press-side quality control process, printers and packaging converters can assure optimum color quality, fast make-ready, and reduced waste.

Benefits

Reports results on screen instantly so press operators can quickly make adjustments, even before color drift is visible to the human eye.

Measures process colors, spot colors, PANTONE® colors, paper color, tone value increase, gray balance, and ink density in less than 10 seconds.

Ensures non-contact with your substrate.

Supports the majority of global graphic arts standards, including M1 to accommodate optical brighteners, M3 for measuring wet ink and full support for GRACoL, SWOP 2013, PSO, and FOGRA 51 and 52.

Directly accesses the PantoneLIVE database for accurate spectral target values for corporate and other spot colors and can exchange job data with ColorCert.

One Instrument, Ultimate Flexibility.

Cut your make ready time by more than 30%.

With a push of a button, the eXact Auto-Scan minimizes human error when scanning to maximize speed, reduce rework, and deliver a finished product that meets your customers tight tolerances.

Improve Color Quality

Enhances spot color handling with creation and management of standards and color libraries on your device. Reduces variance among your instruments and verifies and/or profiles your device anytime on site with the addition of NetProfiler software

Reduce Material Waste

Fast, press-side, fully-automated capabilities (readings under 15 seconds), results in a reduction in waste and increased profitability. Increases workflow productivity by running jobs to specific targets and standardizing your production process

Provides immediate, comprehensive reporting of color data through Bluetooth technology, allowing you to make prompt adjustments to the press run

Expand Your Workflow

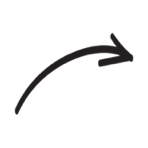

Integrates with closed loop and third-party solutions such as Rutherford Graphics or Digital Information to deliver a mid-range solution for ink key control adjustments

Incorporates into your current workflow

Copyright © 2023 Rutherford. — All rights reserved.

Setting the Standard for Color Measurement

Specifically designed for printers and packaging converters, the eXact Standard is the market leading spectrophotometer to validate the color of CMYK and spot color inks. It leverages job-based tools with industry color standards to increase press process control and connects with PantoneLIVE and NetProfiler to maximize color accuracy within the workflow.

Streamline Jobs on Press with Print Standard Support

The eXact Standard doesn't just provide density metrics and colorimetric value functions, it also supports all industry print standards: G7, ISO, PSO, and Japan Color. Plus, the BestMatch feature offers guidance to help you achieve a closer match to a specific color standard by adjusting ink on press.

Best in Spot Color Support

The eXact Standard offers the ability to create and manage standards and color libraries directly from the device for enhanced spot color handling. It also delivers direct and seamless access to the latest Pantone libraries and PantoneLIVE standards with an optional license.